Micro-bubble_Generator

Solutions_for_DAF/mixing_and_microbubble_applications

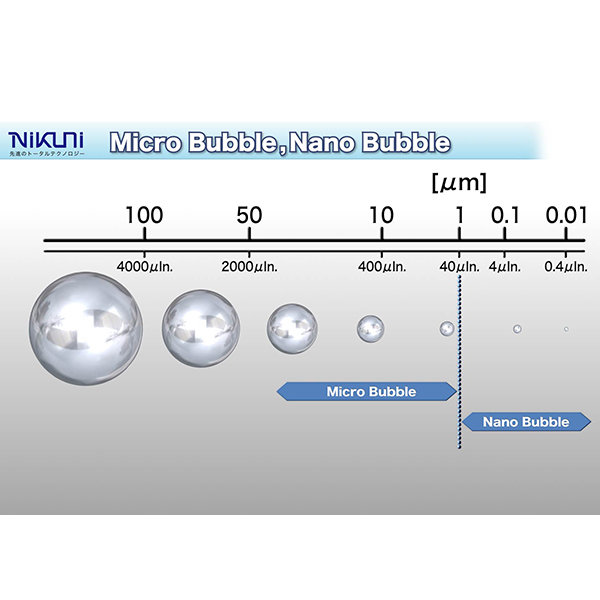

Micro-bubbles Generator

Micro-bubble_Generator Solutions_for_DAF/mixing_and_microbubble_applications

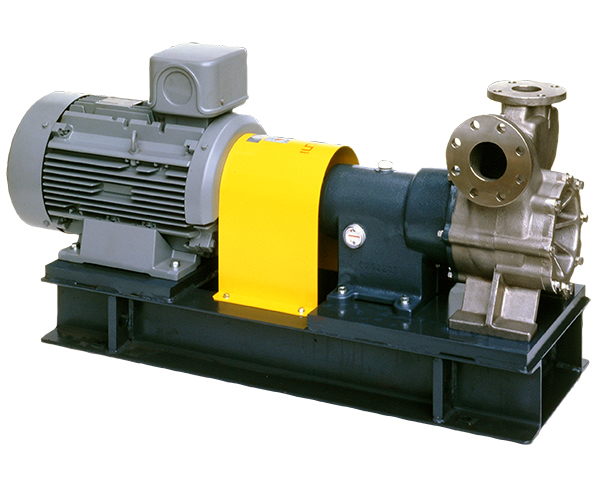

KTM

Applications

Waste water treatment plants for food, beverage, dairy, seafood, poultry processing, laundries, bakeries etc.Dringking water treatment and disalination plants

Municipal waste water plant and power station

Automotive and chemical plants

Petroleum or oil & gas plants

Paper mill or textile industries

Features

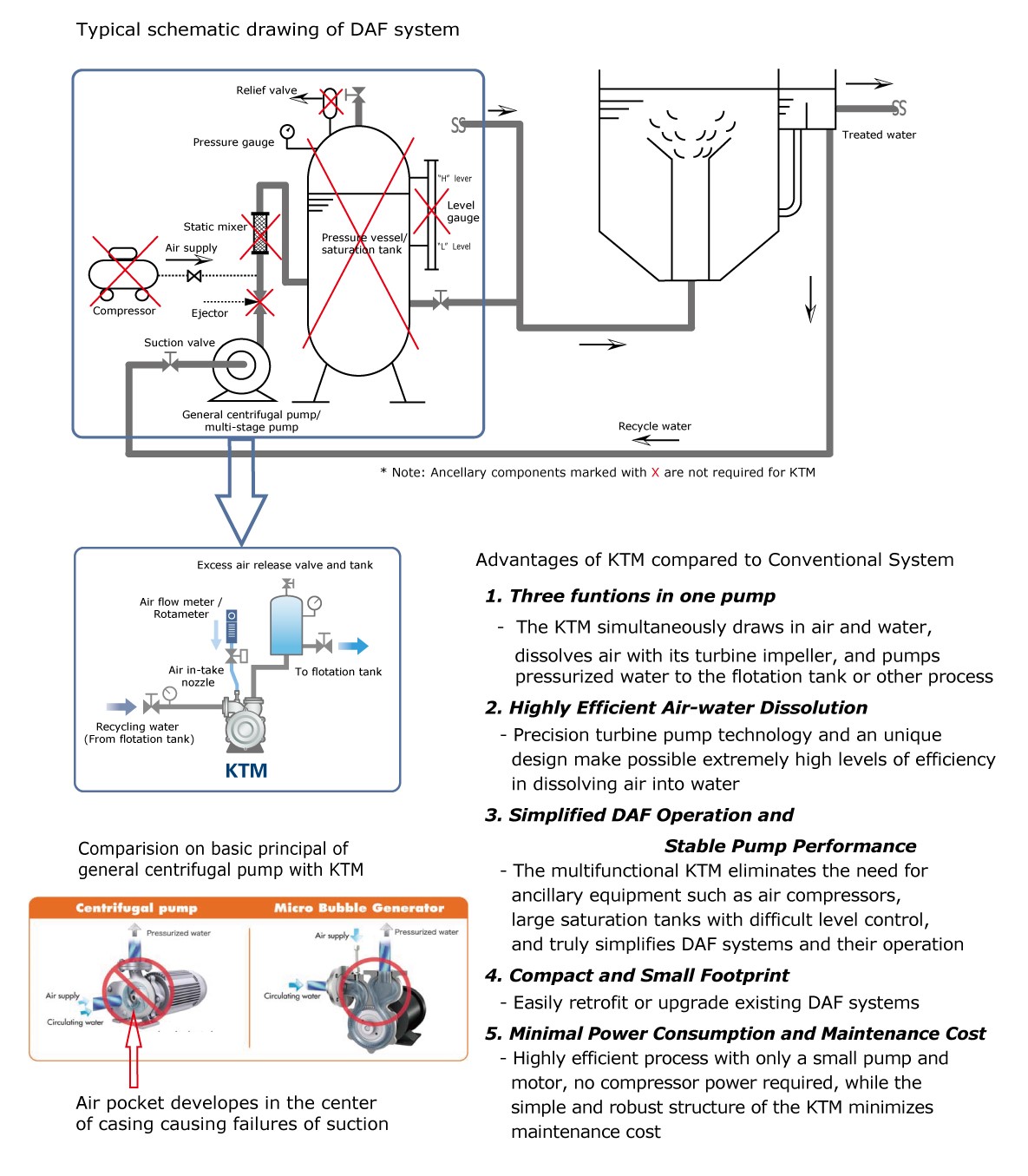

Three functions in one pump- Simultaneously draws in air and water,dissolves air with its turbine impeller, and pumps pressurized water to flotation tank or other process

Highly efficient air-water dissolution

- Precision turbine pump technology and unique design make possible extremely high levels of efficiency in dissolving air into water

Simplified DAF operation with stable pump performance

- The multifunctional KTM eliminates the need for ancillary equipments and simplifies DAF operation

Compact in size and small footprint

- Easily retrofit or upgrade existing DAF systems

Minimal power consumption and save maintenance cost

- Highly efficient process with small pump and motor, no compressor power required, while the simple and robust structure of the KTM minimizes maintenance cost

Performance

| Coupling connection / Base-mounted model | |||||||||

| Model | 50Hz frequency | 60Hz frequency | |||||||

| Water flow rate | Air flow rate | Required motor power |

Water flow rate | Air flow rate | Required motor power |

||||

| L / min | m3 / Hr | nL / min (Range) * | kW / pole | L / min | m3 / Hr | nL / min (Range) * | kW / pole | ||

| KTM20F / N | 17 | 1.0 | 1.3 (0 to 5) | 0.75 kW / 2 P | 22 | 1.3 | 1.7 (0 to 5) | 0.75 kW / 2 P | |

| KTM25F / N | 25 | 1.5 | 2.0 (0 to 5) | 1.5 kW / 2 P | 42 | 2.5 | 3.3 (0 to 5) | 1.5 kW / 2 P | |

| KTM32F / N | 50 | 3.0 | 4.0 (0 to 10) | 2.2 kW / 2 P | 67 | 4.0 | 5.3 (0 to 10) | 2.2 kW / 2 P | |

| KTM40F / N | 80 | 4.8 | 6.4 (0 to 20) | 3.7 kW / 2 P | 117 | 7.0 | 9.3 (0 to 20) | 3.7 kW / 2 P | |

| KTM50F1 (D) / S1(D) | 133 | 8.0 | 11.0 (0 to 20) | 5.5 kW / 4 P | 192 | 11.5 | 15.0 (0 to 20) | 7.5 kW / 4 P | |

| KTM50F2 (D) / S2(D) | 200 | 12.0 | 16.0 (0 to 20) | 7.5 kW / 4 P | 250 | 15.0 | 20.0 (0 to 30) | 11 kW / 4 P | |

| KTM50F3 (D) / S3(D) | 250 | 15.0 | 20.0 (0 to 30) | 11 kW / 4 P | 300 | 18.0 | 24.0 (0 to 40) | 15 kW / 4 P | |

| KTM65SF2 (D) / S2 (D) | 333 | 20.0 | 27.0 (0 to 40) | 15 kW / 4 P | 467 | 28.0 | 37.0 (0 to 60) | 18.5 kW / 4 P | |

| KTM80SF (D) / S (D) | 700 | 42.0 | 56.0 (0 to 80) | 22 kW / 4 P | 967 | 58.0 | 77.0 (0 to 100) | 30 kW / 4 P | |

| Close-coupled / Monoblock model | |||||||||

| KTM20FD / ND -04P (S) | 17 | 1.0 | 1.3 (0 to 5) | 0.56 kW / 2 P | Not available for 60Hz frequency | ||||

| KTM20FD / ND -07P (S) | Not available for 50Hz frequency | 22 | 1.3 | 1.7 (0 to 5) | 0.975 kW / 2 P | ||||

| KTM25FD / ND-07P | 25 | 1.5 | 2.0 (0 to 5) | 0.975 kW / 2 P | Not available for 60Hz frequency | ||||

| KTM25FD / ND-15P | Not available for 50Hz frequency | 50 | 3.0 | 4.0 (0 to 10) | 2.2 kW / 2 P | ||||

| KTM32FD / ND-15P | 50 | 3.0 | 4.0 (0 to 20) | 1.975 kW / 2 P | 80 | 4.8 | 6.4 (0 to 20) | 3.7 kW / 2 P | |

| KTM40FD / ND-22P | 80 | 4.8 | 6.4 (0 to 20) | 3.7 kW / 2 P | 80 | 4.8 | 6.4 (0 to 20) | 3.7 kW / 2 P | |

| Remarks | |||||||||

| * 1 Values in brackets show the recommended range of flow meter or rotamenter. | |||||||||

| 2 Model code and material | |||||||||

| - F = Wetted parts in cast iron with stainless steel impeller & shaft. | |||||||||

| - N / S = Wetted parts in standard SS304 material. SS316 as optional material is also availalble. | |||||||||

| 3 Flow rates reflected to KTM discharge pressure at 0.4 Mpa / 4 Bar / 56 psi and 8% of air injection. | |||||||||

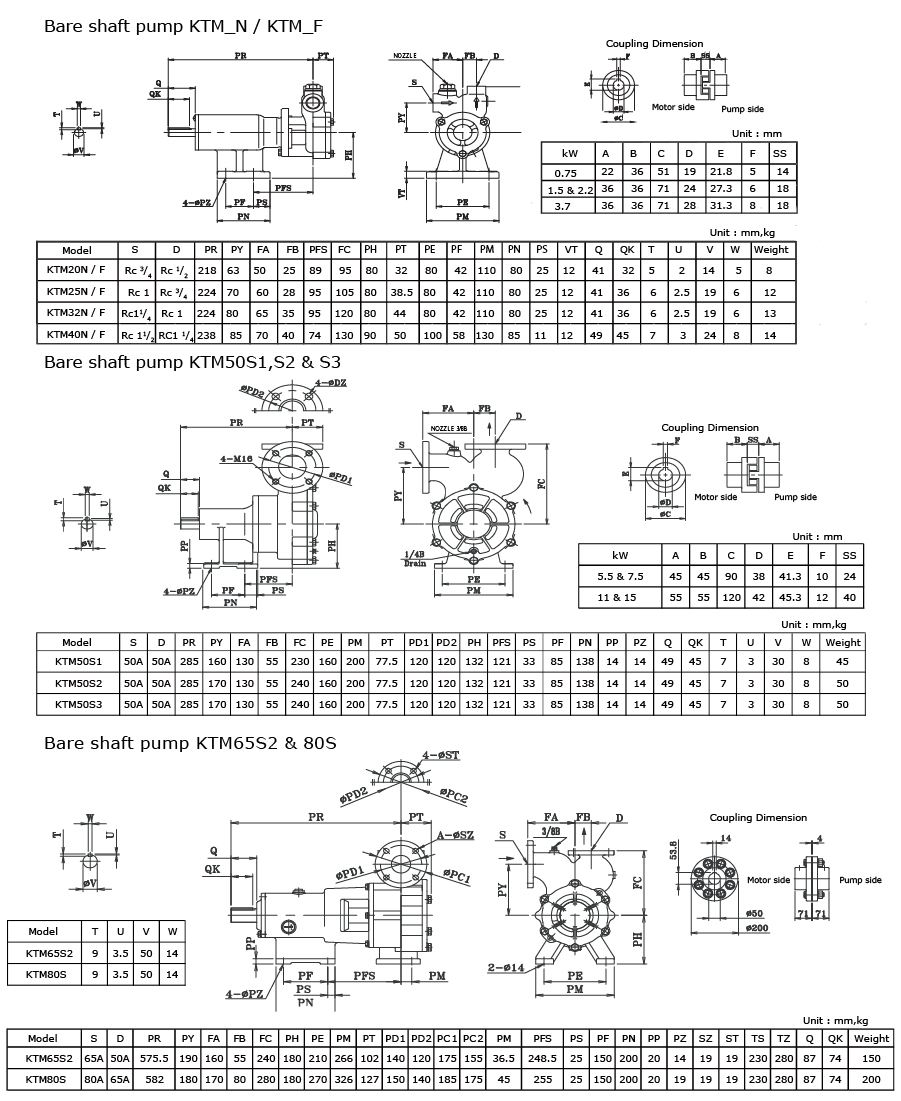

Specification Data

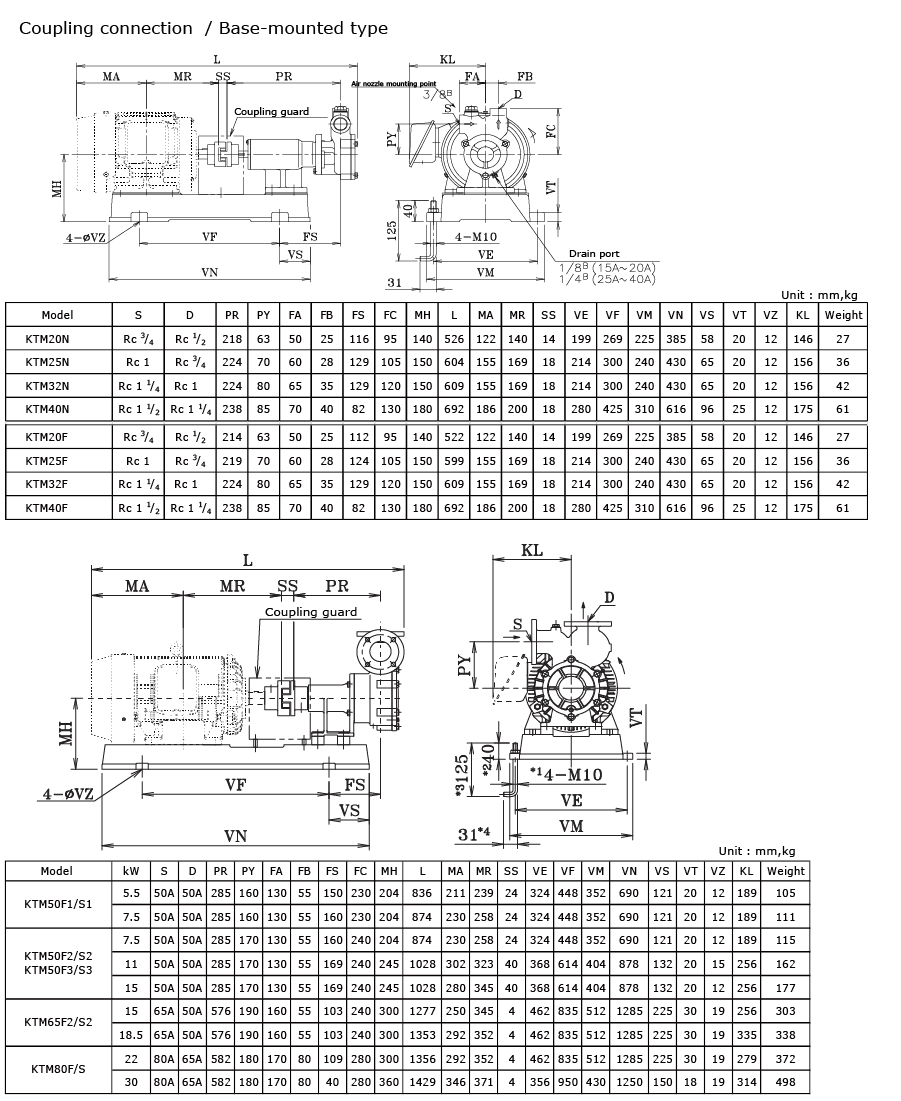

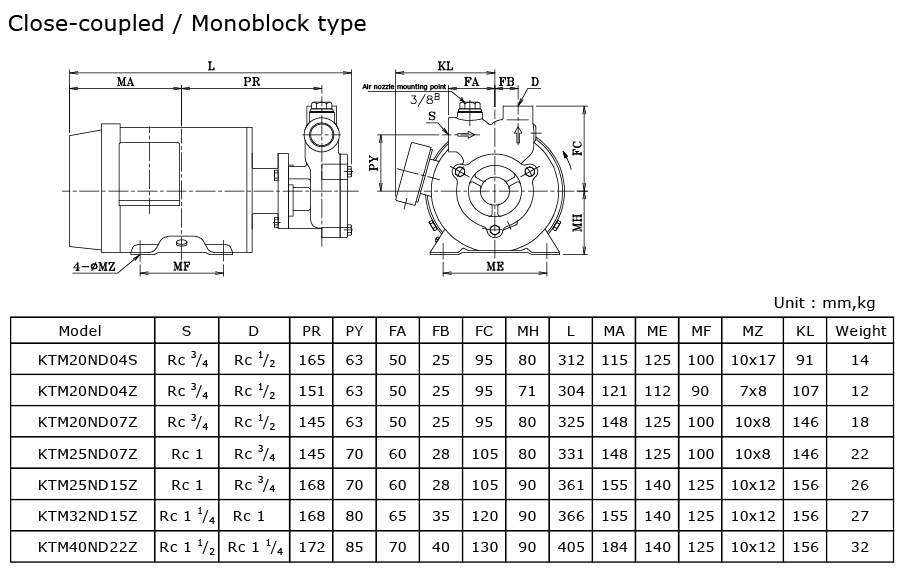

Dimensions

Nikuni has developed a unique and compact Micro-Bubble Generator - the KTM - that creates pressurized air-enriched whitewater with highly reliable performance, insuring excellent stability in processes and systems such as DAF units in water treatment plants