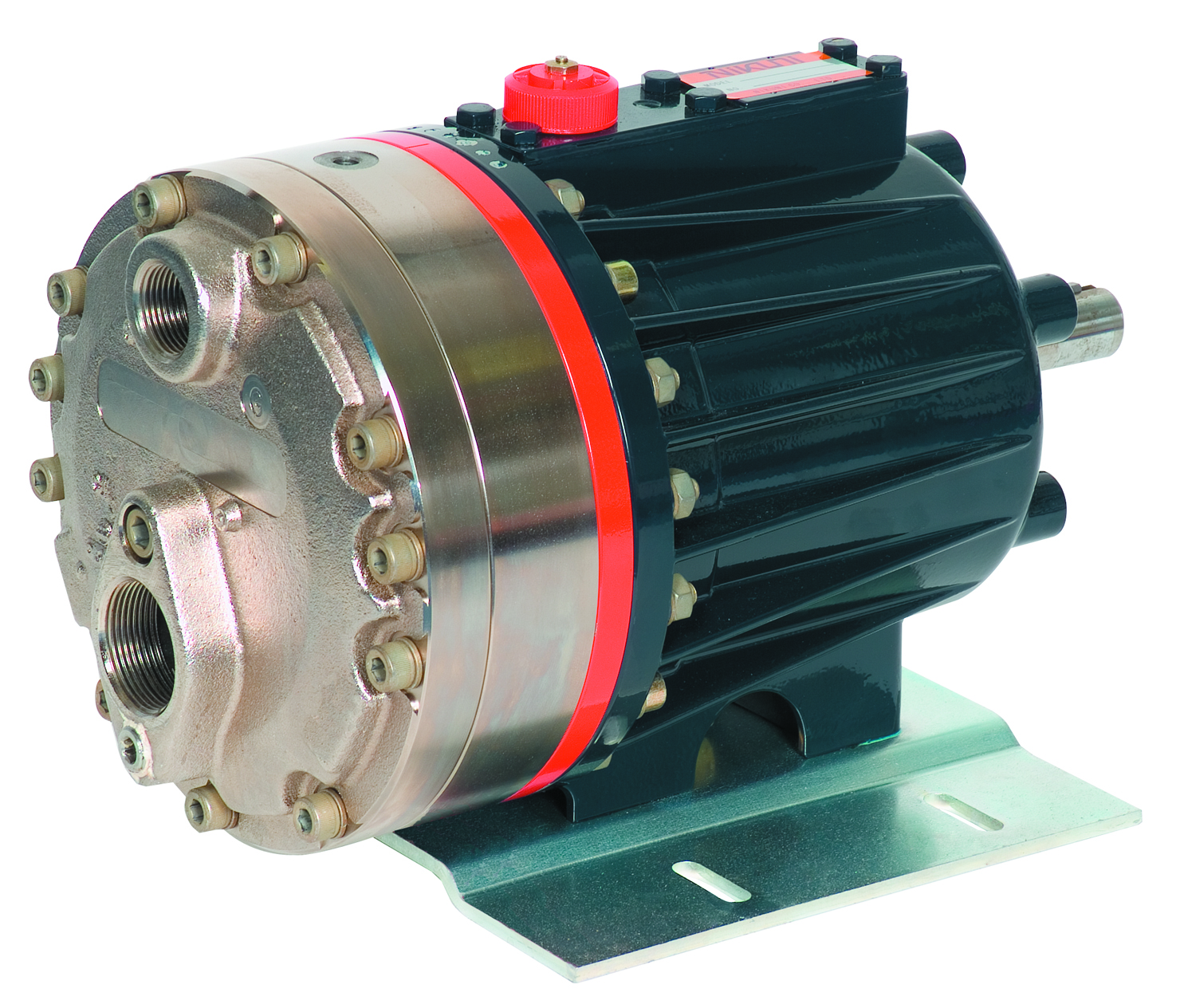

Hydra-Cell_Pumps

Heavy_duty_industrial_pump

Positive displacement diaphargm pump

Hydra-Cell_Pumps Heavy_duty_industrial_pump

25HY

Pump efficiency up to 85%, Hydra-cell pumps enable to handle fluids containing abrasive or particulates

Applications

Transferring fluids with abrasive or particulates in high pressureTransferring coolant

Removing labels from pallets or containers

High pressure washing application of lime water or waste water

Vehicle washing machines

High pressure hydro cyclone application

Features

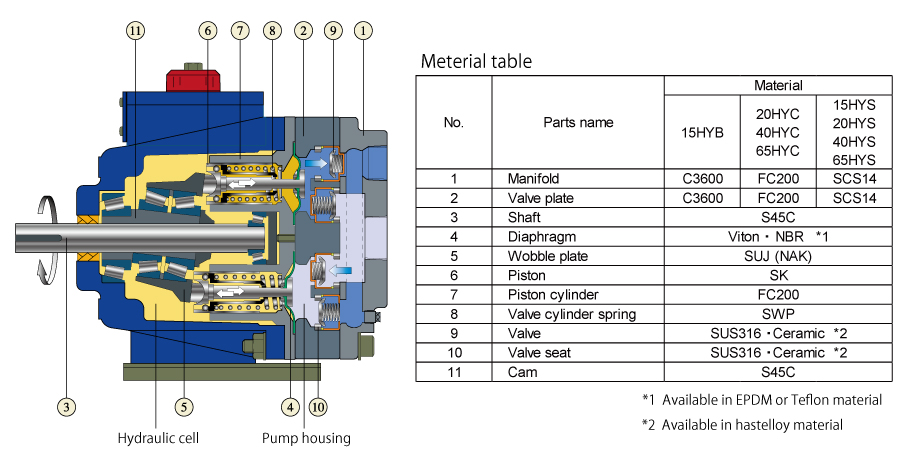

Hydra-Cell positive displacement pumps feature a sealless pumping chamber and hydraulically-balanced diaphragm design, enabling the pumps to provide leak-free, low-maintenance performance while processing difficult fluids over a wide range of pressures and flows.

Hydra-Cell pumps can run dry without damage and will handle abrasives and particulates (up to 500 microns) that can destroy other pumps.

Multiple diaphragms minimize pulsations, so Hydra-Cell operates virtually pulse-free, often eliminating the need for expensive pulsation dampeners.

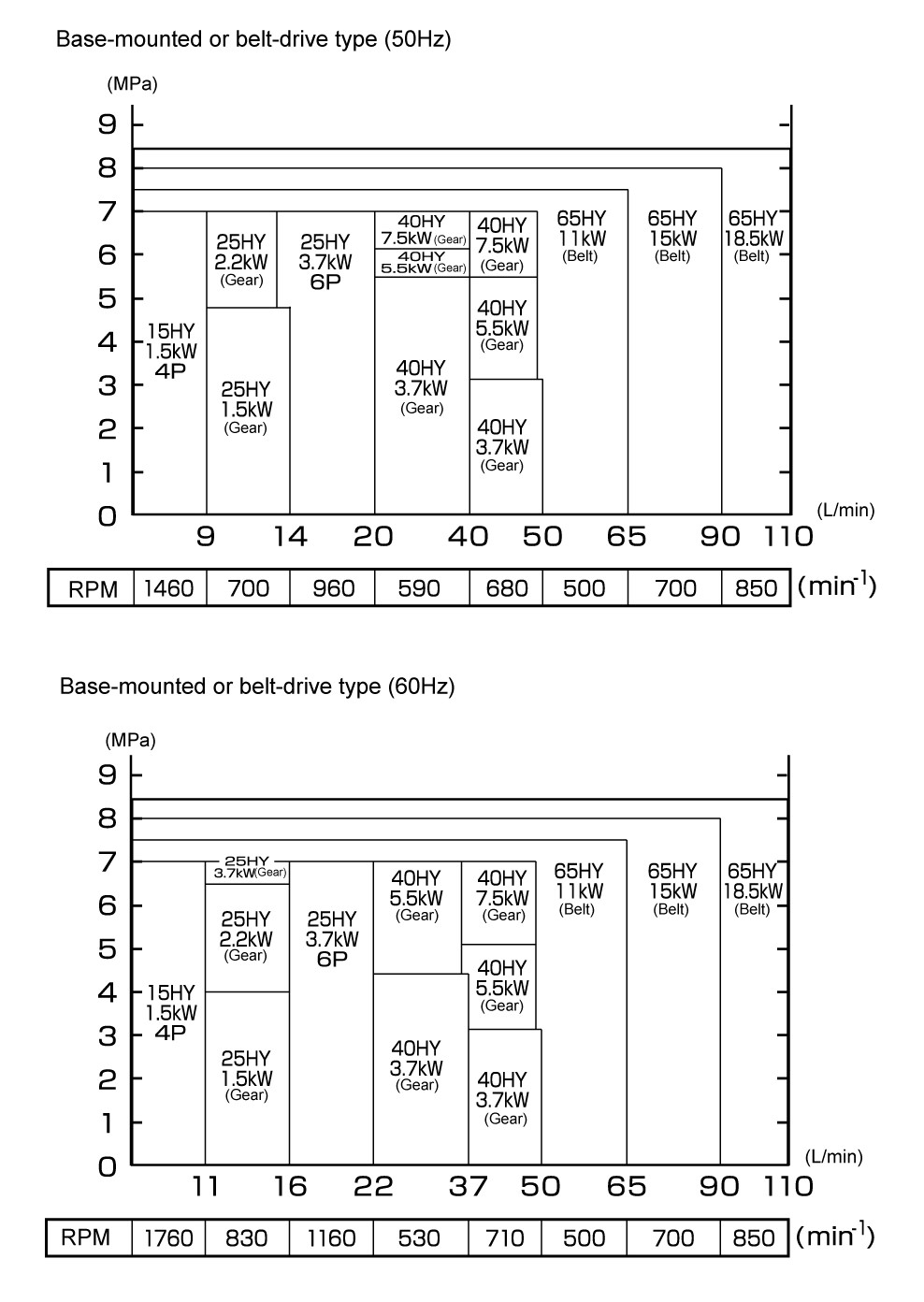

Performance

Specification Data

1. High pressure and high efficiency

Having lubricant filled in the lubricating oil bath portion, rotation power of the motor drive shaft can be efficiently transformed to pressure energy. 85% pump efficiency achievable from low to high pressure (~7 MPa) ranges.

2. Transferring fluids containing abrasives or particulates with high pressure

Due to the diaphragms are installed between pumping chamber and oil pressure chamber (driven section), damage caused by slurry would not be happened at the driven section, resulting long lifetime and maintaining high performance operation.

3. Low operation noise, less pulsation

Multiple constructions enable to run with high revolution. Movement of the diaphragms is driven by oil pressure, resulting low pulsation and low noise operation.

4. Easy operation

Featured with seal-less construction, eliminates trouble caused by seal portion. Self-priming capability, can be run without water priming process. Transferring fluids regardless to the shaft rotating direction.

5. Easy maintenance

Replacement of diaphragms or valves can be done without the need of removing the pump. Resulting short term suspension and less maintenance work.

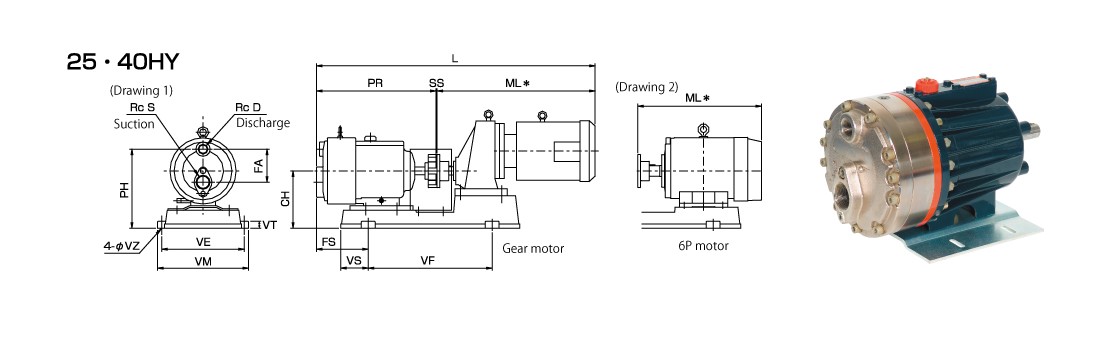

Dimensions

Dimension Table

| Model | Motor | Diameter | CH | FA | FB | PH | PR | L | ML | H | VE | VF | VM | VN | VS | VT | VZ | FS | SS | Weight (kg) |

||

| kW | Pole | S | D | |||||||||||||||||||

| 15HY | 1.5 | 4 | 1/2 | 3/8 | 90 | 38 | 51 | 109 | 178 | 470 | 279 | - | 140 | 125 | 176 | 149 | - | 10 | 10x12 | 164 | - | 42.5 |

| Gear motor | ||||||||||||||||||||||

| 25HY | 1.5 | RX57 | 1 | 3/4 | 173 | 86 | - | 230 | 283 | 770 | 483 | - | 280 | 425 | 310 | 610 | 93 | 25 | 12 | 50 | 4 | 72 |

| 2.2 | RX57 | 1 | 3/5 | 173 | 86 | - | 230 | 283 | 816 | 529 | - | 280 | 425 | 310 | 610 | 93 | 25 | 12 | 50 | 4 | 83 | |

| 3.7 | 6P | 1 | 3/6 | 204 | 86 | - | 261 | 283 | 737 | 450 | - | 324 | 448 | 354 | 690 | 121 | 25 | 12 | 110 | 4 | 111 | |

| 40HY | 3.7 | RX67 | 1 1/2 | 1 | 208 | 120 | - | 287 | 432 | 1023 | 587 | - | 300 | 450 | 330 | 650 | 100 | 25 | 12 | 183 | 4 | 138 |

| 5.5 | RX77 | 1 1/2 | 1 | 208 | 120 | - | 287 | 432 | 1092 | 656 | - | 300 | 450 | 330 | 650 | 100 | 25 | 12 | 183 | 4 | 159 | |

| 7.5 | RX77 | 1 1/2 | 1 | 208 | 120 | - | 287 | 432 | 1109 | 673 | - | 300 | 450 | 330 | 650 | 100 | 25 | 12 | 183 | 4 | 177 | |

| Belt-drive | ||||||||||||||||||||||

| 65HY | 11 | - | 2 1/2 | 1 1/4 | 395 | 104 | 205 | 499 | - | - | - | 700 | 690 | 950 | 750 | 1250 | 150 | - | 19 | 164 | - | 506 |

| 15 | - | 2 1/2 | 1 1/4 | 395 | 104 | 205 | 499 | - | - | - | 700 | 690 | 950 | 750 | 1250 | 150 | - | 19 | 164 | - | 533 | |

| 18.5 | - | 2 1/2 | 1 1/4 | 395 | 104 | 205 | 499 | - | - | - | 700 | 690 | 950 | 750 | 1250 | 150 | - | 19 | 164 | - | 585 | |

| 22 | - | 2 1/2 | 1 1/4 | 395 | 104 | 205 | 499 | - | - | - | 700 | 690 | 950 | 750 | 1250 | 150 | - | 19 | 164 | - | 595 | |