MSE_(Multi-stacked_elements)_Mixer

Nipple_Mixer

MSE

MSE_(Multi-stacked_elements)_Mixer Nipple_Mixer

NiM

Applications

Applications- Mixing gases or liquids.

- Bubbles dispersion in liquids.

- Dilution, concentration adjustment, pH adjustment.

- Mixing gases with large flow or concentration differences.

Apllication examples

- Gas Mixing

- Liquid Mixing

- Gas-Liquid Mixing

Features

- High mixing capability

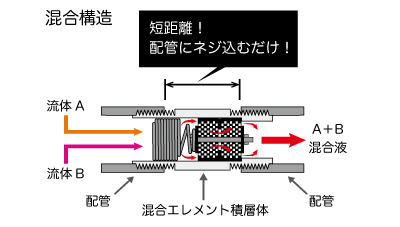

- Enables mixing with short piping distance

Performance

Structure and Mechanism

- Two types of differently shaped mixed elements stacked alternately, tucked with blind plate and ring plate create complex flow paths in both axial and radial directions.

- Supplied fluids repeatedly divide and merge through these flow paths, efficiently demonstrating high stirring capacity due to generated turbulence and vortices.

Structural components

Visualization of bubbles dispersion in water flow

*Please check below video for details.

Efficient mixing by repeatedly dividing and merging in axial and radial directions