Filtration_Products

Other_products

KASUMI oil_skimmer

Filtration_Products Other_products

OSK

Prevents decay and bad odors for coolant and washing fluids

Applications

The Nikuni oil skimmer, Kasumi, is equipped with a special belt and effectively removes tramp oil--machine lubricant oil and broken-down emulsion oil from the machine coolant--from the surface of the machine tool tank.

Kasumi prevents the emulsion coolant from decaying and odors from anaerobic bacteria by exposing the coolant to air. Kasumi is also equipped with an oil separation tank and reduces coolant disposal

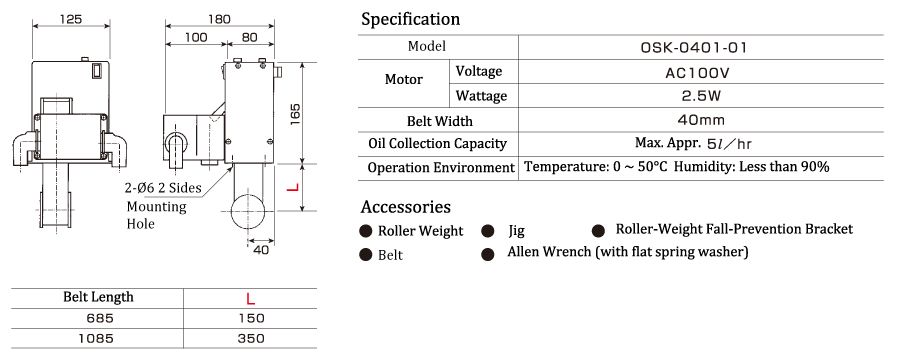

Specification Data

improvement of Working Enviroment

Kasumi maintains a pleasant working environment by preventing odors caused by decayed coolane.Reduction of Industrial Waste

Kasumi extends the life of coolant,reduces the frequency of coolant replacement,and helps lower industrial waste disposal costs.The oil separation tank further reduces

disposal volume by condensing the skimmed fluid.

Cost Saveing

Kasumi reduces coolant consumption and cuts waste disposal costs.It can also help reduce tank cleaning time and increases machine operation time.

Kasumi only uses about $2.50 worth of electricity to run annually.

Simple Design and Easy Operation

Kasumi has a simple design and does not fail.It is easily installed with the provided accessary parts and jigs.

Operation Procedure

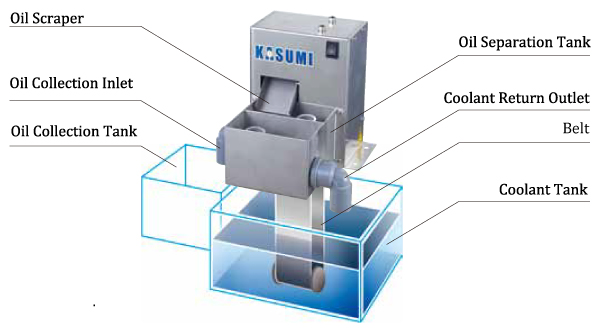

1.With the rotation of the belt, tramp oil and a small amount of coolant are skimmedand lifted up.

2.The skimmed oil and coolant are scraped by the scraper andfall in the oil separation tank.

3.Oil is separated in the oil separation tank due to the difference of the specific gravities,and the usable coolant is returned to the coolant tank.

Only the condensed oil is collected.

Dimensions